Scientific-Technical Services

SCIENTIFIC INFRASTRUCTURE

Equipment / Available techniques

Physical adsorption

Physical adsorption

The physical adsorption of gases is one of the most complete and widespread techniques in the study of the textural characteristics of materials. The knowledge of the porous texture of materials is essential for their application in different industrial processes. This technique allows the characterization of materials by evaluating their surface area and porosity (micro and mesopore volumes, porosity distribution).

EQUIPMENT: Quantacrome Instruments

EQUIPMENT: Quantacrome Instruments

MODELO: NOVA 4200e multigases

Fast adsorption analyzer coupled with four analysis stations, calibrated for working with CO2 at different temperatures (0ºC, 25ºC, 50ºC) or liquid nitrogen.

It accepts solid samples that are finely grinded, dry and stable at degassing temperatures prior to analysis.

Solid samples: powder, grains, pellets, monolithic or fragmented solids, fibers (for piece samples, their size is limited by the internal diameter of the tube, which is 9.5 mm).

SAMPLES:

The samples must be thermally stable with a decomposition temperature higher than the requested degassing temperature. (In cases that the degassing temperature is not indicated, the sample will be degassed at a temperature of 110-150ºC).

The samples must be free, as far as possible, from sulfur and / or hydrocarbons. In the case of catalysts, these should, as far as possible, be free of traces of the precursor.

The amount of sample needed for the analysis is a function of the estimated BET area, and thus, for samples with:

- Area > 10 m2/g: Minimum amount of sample 1-2 g.

- Area 10-100 m2/g: Minimum amount of sample 0.2-1 g.

- Area > 100 m2/g: Minimum amount of sample 0.2 g.

EQUIPMENT: Quantacrome Instruments

MODEL: NOVA 4200e multigases

Fast adsorption analyzer coupled with four analysis stations, calibrated for working with CO2 at different temperatures (0ºC, 25ºC, 50ºC) or liquid nitrogen.

It accepts solid samples that are finely grinded, dry and stable at degassing temperatures prior to analysis.

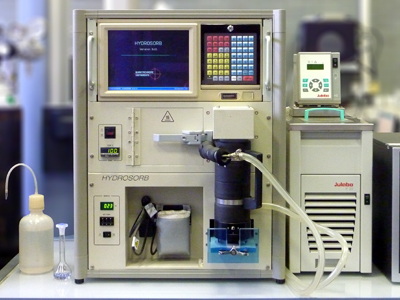

EQUIPMENT: Quantacrome Instruments

MODEL: HYDROSORB 1000 multigases

Fast vapor adsorption analyzer with one analysis station, calibrated for working at different temperatures (0ºC, 25ºC, 50ºC).

It accepts solid samples that are finely grinded, dry and stable at degassing temperatures prior to analysis.

Themogravimetric analysis (TG, DTA, DSC)

Themogravimetric analysis (TG, DTA, DSC)

Thermogravimetry is an analytical technique that allows measuring the weight variation of a sample, versus temperature or time, when a controlled temperature program and a specific atmosphere are applied.

The Service has available two thermobalances:

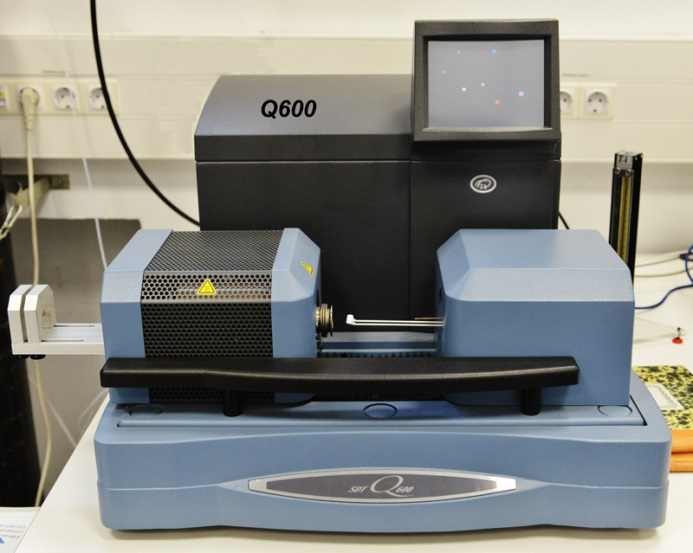

- TA INSTRUMENTS SDT Q600.

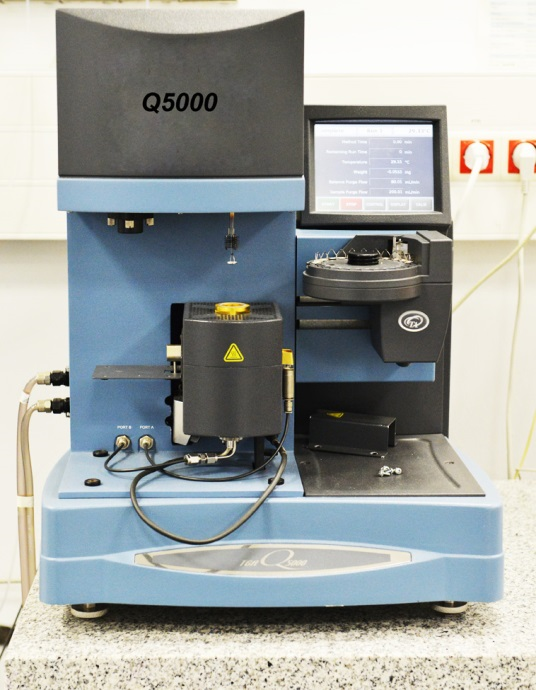

- TA INSTRUMENTS TGA Q5000 IR

The TA INSTRUMENTS SDT Q600 thermobalance has a horizontal furnace that allows analysis from room temperature to 1500 ˚C, with heating ramps from 0.1 to 100 ˚C / min up to 1000 ˚C and from 0.1 to 25 ˚C / min up to 1500 ˚C.

The TA INSTRUMENTS TGA Q5000 IR thermobalance has a vertical furnace that allows analysis from room temperature to 1000 ˚C with a heating ramp from 0.1 to 500 ˚C / min.

TG, DTA (when the reference material is provided) and DSC analyzes can be carried out under several atmospheres: oxygen, argon, air, nitrogen, carbon dioxide and helium.

It is possible to couple both thermobalances to a Pfeiffer Vacuum ThermoStarTM mass spectrometer.

|

|

High pressure balance

High pressure balance

It is employed to determine the adsorption storage capacity for carbon based materials. The equipment that has two permanent lines for CO2 and H2 is available to carry out measurements with other gases (N2, CH4…). It has been widely proven for high-pressure isotherms (until 100 bar for H2).

The amount of simple should be approx. 1 g.

Chromatography

Chromatography

TECHNIQUE: GAS CHOMATOGRAPHY-MASS SPECTROMETRY.

EQUIPMENT: GC System coupled to a quadrupole masss detector.

MODEL: Agilent 7890A y 5975C

DESCRIPTION: It allows getting information about the molecular mass of the analyzed compound, as well as obtaining structural information about it. Specially tuned for the analysis of samples from the petrochemical and carbochemical industries.

SAMPLES: Liquid samples, min. 50 μL and expected concentration around 0.2-1 mg/mL. High purity, FREE OF WATER and witout particles. They must be of low or null polarity, with a molecular weight of 50-800 amu, and be volatile and poorly thermolabile compounds.

It is not possible to analyze by this technique compounds with melting points higher than 400 ºC, or that melt through decomposition or very volatile compounds (sublimable liquids or solids).

The presence of inorganic bases and salts, as well as any non-volatile substance, should be avoided.

Solvents: Volatile: methanol, toluene, dichloromethane, hexane … Avoid DMSO.

TECHNIQUE: GAS CHOMATOGRAPHY-TCD

MODEL: HP 5890 Series II

EQUIPMENT: GC with thermal conductivity detector.

DESCRIPTION: Qualitative and quantitative analysis of refinery gas and similar. It allows the complete analysis of permanent gases and light hydrocarbons in samples of natural gas, refinery gas, etc.

SAMPLES: Gaseous samples, minimum of 200 mL, in a bag for gas3es or gas ampoule provided with a septum.

X-Ray Difraction

X-Ray Difraction

X-ray diffraction is a very useful technique for the structural characterization of materials that present a certain degree of crystallinity. It is based on Bragg’s law.

Thanks to the phenomenon of diffraction, it is possible to resolve the structures of natural products, the qualitative and quantitative identification of the compounds present in a solid sample and the identification of allotropic forms.

It is possible to analyze whole flat pieces (metallic, ceramic, etc.) using our reflectometry table.

It is a non-destructive technique. Minimum amount of sample between 0.5 and 1 gram.

Diffusivity and thermal conductivity

Diffusivity and thermal conductivity

The equipment used is the NETZSCH LFA 457 MicroFlash model: it allows the determination of the thermal diffusivity and conductivity of materials in the range from -125 ° C to 1100 ° C. The front face of a plano-parallel sample is heated by means of a laser, this heat propagates through it and causes an increase in temperature on its rear face, which is measured as a function of time by means of an infrared detector. The thermal diffusivity and conductivity and in many cases also the specific heat can be known using the measured signal.

It is a modern and versatile material characterization system. The equipment has a compact, vacuum-tight construction, and tests can be carried out under defined atmospheres. The vertical arrangement of the sample holder, oven and detector simplifies sample placement while ensuring an optimal signal-to-noise ratio in the detector signal.

Infrared spectroscopy

Infrared spectroscopy

Infrared (IR) spectroscopy is a technique for analyzing substances in the gaseous, liquid or solid state, both crystalline and amorphous, through their absorption or reflection spectrum in the IR range of the electromagnetic spectrum, thus allowing the identification of chemical compounds through the determination of the frequency at which the different functional groups present absorption bands in the IR region.

IR spectroscopy Equipment:

![]()

Large instrument supply being able to analyze solid samples, non-aqueous liquid, aqueous liquid, films, fibers, foams, etc.

Although it is mainly used for the study of organic compounds, inorganic compounds that contain cations or polyatomic anions also give rise to useful infrared spectra.

Raman spectroscopy

Raman spectroscopy

Raman Spectroscopy is a high resolution photonic technique that provides chemical and structural information on almost any organic and / or inorganic material or compound in a few seconds, thus allowing its identification. The analysis by means of Raman spectroscopy is based on the examination of light scattered by a material by indicating on it a monochromatic light beam. A small portion of the light is scattered inelastically undergoing slight frequency changes that are characteristic of the analyzed material and independent of the frequency of the incident light. It is an analysis technique that is carried out directly on the material to be analyzed without the need for any special preparation and that does not entail any alteration of the surface on which the analysis is carried out, that is, it is non-destructive.

The equipment available allows the qualitative analytical study of organic and inorganic molecules in solid and / or liquid state:

Equipment:

Jobin Yvon labRam HR UV 800 dispersive Raman spectrometer (532nm Ar laser and 785nm diodes) with CCD detector and coupled to Olympus BXFM-ILHS confocal microscope.

Nicolet NXR 6700 FT-Raman module (InGaAs detector and 976nm laser).

Competitive advantages:

– Experience in the analysis of materials such as graphites, carbonaceous materials

– Availability of three different types of lasers (532nm, 785nm, 976nm) covering a wider range of materials.

X-Ray Fluorescence

X-Ray Fluorescence

X-ray spectrometry is a non-destructive qualitative and quantitative elemental analysis technique, based on the measurement of wavelengths or X-ray energy, emitted by the sample after being bombarded by primary radiation.

Chemical Analysis by X-Ray Fluorescence (XRF) – Fused bead procedure

The powdered ash (0.5000 g) is fused with 6.0000 g lithium tetraborate (Spectromelt A1000), to destroy its particle and mineralogical composition, at 1200ºC for 11 minutes in a fusion machine (PERL X3 – Philipps).

The resulting melt is cast in the form of a glass bead which is subsequently fed into the XRF spectrometer (SRS 3000 Bruker). In the fused bead, the fluorescence intensities of the x-rays of the required elements are measured and the chemical composition of the ash is analyzed in relation to graphs or calibration equations previously determined and applying corrections for the interelemental effects. Calibration equations and interelemental corrections are established from beads made from certified reference materials.

Competitive advantages

Environmentally friendly, fast, non-destructive.

Measure all elements (Be to U) qualitatively, semi-quantitatively and quantitatively.

Simple and fast sample preparation.

Multi-element analysis capabilities with high precision and reproducibility.

Ash fusibility

Ash fusibility

PRINCIPLE OF THE METHOD

Knowledge of the characteristics of the fusion of the ashes of solid mineral fuels provides information on the behavior of the inorganic components of these fuels when they are subjected to high temperatures. With the ashes of a fuel, a test probe is prepared then, under observation, it is heated in a tube furnace using standardized conditions. The temperatures at which the probe undergoes characteristic changes are considered.

These temperatures are:

Deformation temperature: Temperature at which the first signs of rounding of the vertex or upper vertices of the apparent shape of the probe appear.

Hemisphere temperature: Temperature at which the profile of the test piece takes the apparent shape of a semicircle, that is, when the height of the profile of the test piece is equal to half its base.

Flow temperature: Temperature at which the mass of the ashes spreads over the support in a layer whose maximum height is equal to one third of the height of the profile of the probe at the hemisphere temperature

COMPETITIVE ADVANTAGES

– There are two automatic Ash Fusibility equipments capable of simultaneously processing up to six samples in each one.

– Fully automated equipment with an image acquisition and treatment device.

– Possibility of measurement in oxidizing or reducing atmospheres.

ICP-MS

ICP-MS

Inductively Coupled Plasma Mass Spectrometry (ICP-MS) is an instrumental, multielemental analysis technique, with a wide linear range and high sensitivity, capable of detecting and quantitatively determining the vast majority of the elements included in the periodic system.

The equipment available at INCAR is an Agilent brand ICP-MS 7700x, with He collision cell to eliminate matrix interferences.

He Picnometry

He Picnometry

EQUIPMENT: MICROMERITICS

MODEL: AccuPyC 1330

DESCRIPTION:

This analyzer is used to measure the density of the solid skeleton using helium gas as the pycnometric fluid. It allows the analysis of solid and semi-solid samples.

COMPETITIVE ADVANTAGES:

It is a fast and completely automated equipment. It allows the precise analysis of samples of a great variety of materials in very diverse forms, such as fine powder, grains, pellets, monolithic or fragmented solids, fibers. It even admits certain semi-solid materials.

Different sizes of analysis chambers are available to suit each material.

SAMPLES:

Solid samples: powder, grains, pellets, monolithic or fragmented solids, fibers … (the size of the pieces is limited by the diameter of the analysis chambers, which is approximately 1.3 cm).

The amount of sample required for the analysis is of the order of 0.5 to 3 g.

Hg Porosimetry

Hg Porosimetry

Hg injection porosimetry is a technique used in the characterization of the macroporous system of materials. It is based on the application of pressure and thus forcing the entry of mercury into the porous framework of the solid. This technique is used in the study of materials that present macropores and mesopores, being able to measure pores of size up to 6 nm; With this analysis, the area, the volume of macro and mesopores are determined and the distribution of the porosity of the material is calculated.

EQUIPMENT: MICROMERITICS

MODEL: AUTOPORE IV 9500

It is a modern and automatic equipment designed to process two samples simultaneously under low pressure and one high pressure.

Large instrument set being able to analyze solid samples in different shapes and sizes (powder, grain, piece, fibers … in the case of pieces, the size is limited by the size of the penetrometer capsule, which has an internal diameter of approximately 1.5 cm).

SAMPLES:

Solid samples: powder, grains, pellets, monolithic or fragmented solids, fibers … (the size of the pieces is limited by that of the penetrometer capsule, which has an internal diameter of approximately 1.3 cm).

It is a destructive technique so the sample being analyzed is lost.

The amount of sample required for the analysis is of the order of 0.5 to 1 g (however, it is recommended to send more quantity, 3 g, for different unforeseen events).

SEM

SEM

Quanta FEG 650 field emission scanning electron microscope. It has an S / TEM detector. It is fitted with an X-ray dispersive energy analyzer (Ametek-EDAX. Detector: Apollo X)

Advantage:

– It can work in 3 modes: high vacuum, low vacuum and ESEM

– Diversity of detectors: Everhart-Thornley, Backscattered electron, Large field, Gaseous secondary electron and scanning transmitted electron microscopy.

TOC

TOC

The equipment used is the SHIMADZU TOC-VCPH E200V Total Organic Carbon Analyzer. It has a number of add-ons: an autosampler for liquid samples (ASI -V), a module for solid samples (SSM-5000A), and a total nitrogen analysis module (TNM-1). Together they allow the determination of total carbon, total inorganic carbon, and total organic carbon present in both solid and liquid samples, and that of total nitrogen present in liquid samples. Carbon measurement is carried out by a catalytic combustion-oxidation procedure followed by non-dispersive infrared analysis, while that of nitrogen by thermal decomposition and chemiluminescence analysis.

COMPETITIVE ADVANTAGES

The TOC analyzer performs efficient analysis thanks to its ability to oxidize difficult-to-decompose compounds. It allows a wide measurement range, from ultra pure water to highly concentrated samples, not being necessary to use large quantities of sample for analysis, and requiring a short measurement time.

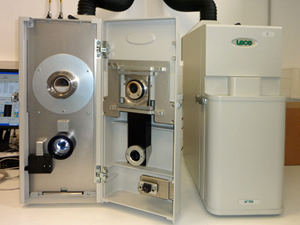

XPS

XPS

X-ray photoelectron spectroscopy (XPS) is an analysis technique applied to solid samples compatible with ultra-high vacuum. Information is obtained on the chemical composition of the most superficial layer of the sample (~ 10 nm thick). All elements except the lightest ones (H and He) are detected. The detection limit increases with the atomic number of the element and is around 0.1-0.5 atomic%. Therefore, it is not a question of trace analysis, since the maximum is parts per thousand. The technique can also provide information on the chemical environment and oxidation state of each of the elements detected.

X-ray photoelectron spectroscopy (XPS) is an analysis technique applied to solid samples compatible with ultra-high vacuum. Information is obtained on the chemical composition of the most superficial layer of the sample (~ 10 nm thick). All elements except the lightest ones (H and He) are detected. The detection limit increases with the atomic number of the element and is around 0.1-0.5 atomic%. Therefore, it is not a question of trace analysis, since the maximum is parts per thousand. The technique can also provide information on the chemical environment and oxidation state of each of the elements detected.